Prototypes and special orders case 1

I want to carburize as thick as possible.

It is possible to achieve a maximum of 3 mm in effective thickness of a hardened layer.

Please consult with us about your request with a drawing. The effective size is up to Ф800 x 1600.

It is possible to achieve a maximum of 3 mm in effective thickness of a hardened layer.

Please consult with us about your request with a drawing. The effective size is up to Ф800 x 1600.

Also, Metal Heat Treatment Solution has been performing various types of heat treatment on prototypes.

Prototypes and special orders case 2

I want advice on a trial production using carbon tool steel.

This was a consultation on a fixed base for pipe cutting.

Salt bath quenching of the original material had caused distortion. So, we inquired about the intended use and found that only the rubbed part had to be hardened. So, we proposed to change the material from carbon tool steel to general-purpose cold rolled steel and also to change the heat treatment method to gas soft nitriding.

As a result, we could reduce the total cost to 2/3 of the previous cost and increase the life span of the mold by 50%.

Prototypes and special orders case 3

I want to apply TH treatment to stainless steel SUS631 pipes.

TH treatment can be applied in the vacuum heat treatment.

Prototypes and special orders case 4

I want to request a heat treatment test.

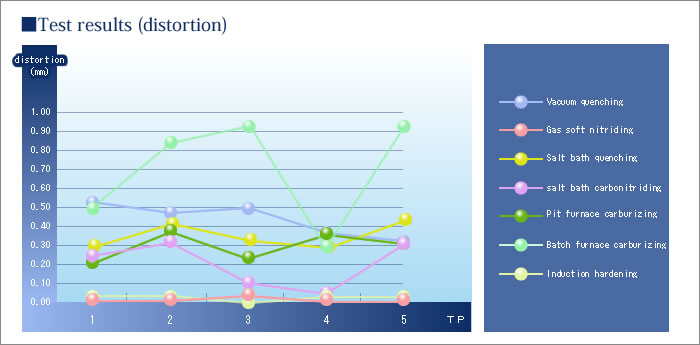

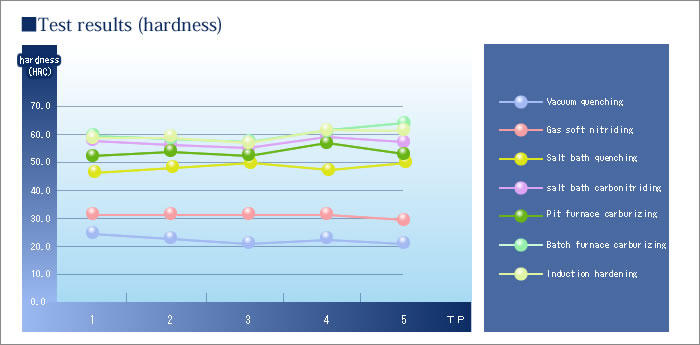

A certain shaft manufacturer requested us to conduct a heat treatment test to find out the optimized heat treatment method by usage.

Purpose

Data collection (Hardness and distortion after heat treatment)

Material

Ф25.2 x 500 mm (S55C peeled steel)

Implementing heat treatment

Vacuum quenching, full quenching (nitrogen atmosphere, oil cooling), carburizing (pit furnace, salt bath cooling), salt bath quenching, salt bath carbonitriding, induction hardening, gas soft nitriding

Results

| ・ | Nitriding had the least distortion. Size rarely changes in nitriding due to its low treatment temperature. It has superb wear resistance (around HV700), but its hardened layer is thin (15 to 20 µm), so it is not recommended for use under pressure. |

|---|---|

| ・ | To reduce distortion while keeping wear resistance and toughness, the most suitable method would be induction hardening or carburizing. The result shows the effectiveness of our company's original induction hardening equipment that suppresses distortion during quenching. |

| ・ | If hardness is needed on the inside while distortion has to be suppressed, salt bath quenching is most suitable. The salt liquid has excellent thermal conductivity, so it heats up and cools down uniformly to treat with low distortion. Also, our original blend of salt liquid carburizes the thin surface of products to allow high hardness with low carbon content. |

| ・ | It was verified that a pit furnace yields less distortion than a batch furnace. The longer the piece size is, the more significant this trend. |

| Heat treatment | Before heat treatment: distortion (mm) | After heat treatment: distortion (mm) | Distortion avg. (mm) | Surface hardness* Nitriding is a converted value. | Surface hardness Avg. (HRC) |

|---|---|---|---|---|---|

| Full quenching (Vacuum atmosphere) * Vacuum heat up, oil cooling |

0.03 | 0.52 | 0.438 | 24.0 | 22.6 |

| 0.02 | 0.48 | 22.5 | |||

| 0.03 | 0.49 | 22.0 | |||

| 0.02 | 0.37 | 23.0 | |||

| 0.02 | 0.33 | 21.5 | |||

| Full quenching (Nitrogen atmosphere) * Atmosphere heat up, oil cooling |

0.02 | 0.51 | 0.702 | 32.0 | 31.7 |

| 0.03 | 0.85 | 32.0 | |||

| 0.02 | 0.93 | 32.0 | |||

| 0.02 | 0.29 | 32.0 | |||

| 0.02 | 0.93 | 30.5 | |||

| Full quenching (Salt bath) * Salt bath heat up, salt bath cooling |

0.02 | 0.29 | 0.346 | 47.0 | 49.1 |

| 0.02 | 0.41 | 49.5 | |||

| 0.03 | 0.32 | 50.0 | |||

| 0.02 | 0.28 | 48.5 | |||

| 0.02 | 0.43 | 50.5 | |||

| Carburizing (Pit furnace) * Atmosphere heat up, salt bath cooling |

0.02 | 0.21 | 0.286 | 52.0 | 53.5 |

| 0.02 | 0.36 | 55.0 | |||

| 0.02 | 0.23 | 53.0 | |||

| 0.02 | 0.34 | 55.0 | |||

| 0.02 | 0.29 | 52.0 | |||

| Carbonitriding (Salt bath) * Salt bath heat up, salt bath cooling |

0.02 | 0.23 | 0.202 | 58.5 | 58.4 |

| 0.03 | 0.32 | 58.0 | |||

| 0.02 | 0.10 | 57.5 | |||

| 0.02 | 0.06 | 59.5 | |||

| 0.02 | 0.30 | 58.5 | |||

| Induction hardening | 0.02 | 0.02 | 0.022 | 58.5 | 59.4 |

| 0.03 | 0.02 | 60.0 | |||

| 0.02 | 0.03 | 59.0 | |||

| 0.03 | 0.02 | 59.0 | |||

| 0.02 | 0.02 | 60.5 | |||

| Gas soft nitriding | 0.02 | 0.02 | 0.012 | 61.0 | 60.8 |

| 0.02 | 0.01 | 60.0 | |||

| 0.03 | 0.00 | 59.0 | |||

| 0.02 | 0.01 | 61.0 | |||

| 0.02 | 0.02 | 63.0 |

For details of equipment specifications, please refer to the "Equipment" section in "Heat Treatment technology of the Solution" page.

Heat treatment method

We own various equipment including vacuum heat treatment, salt bath heat treatment, carburizing heat treatment, induction hardening, nitriding heat treatment, etc.

We also own various testing instruments, such as sub-zero equipment, various hardness testers, metallographic examination equipment and coercive force meters.